Tension Control Systems: Enabling High-Quality Precision Manufacturing

Introduction

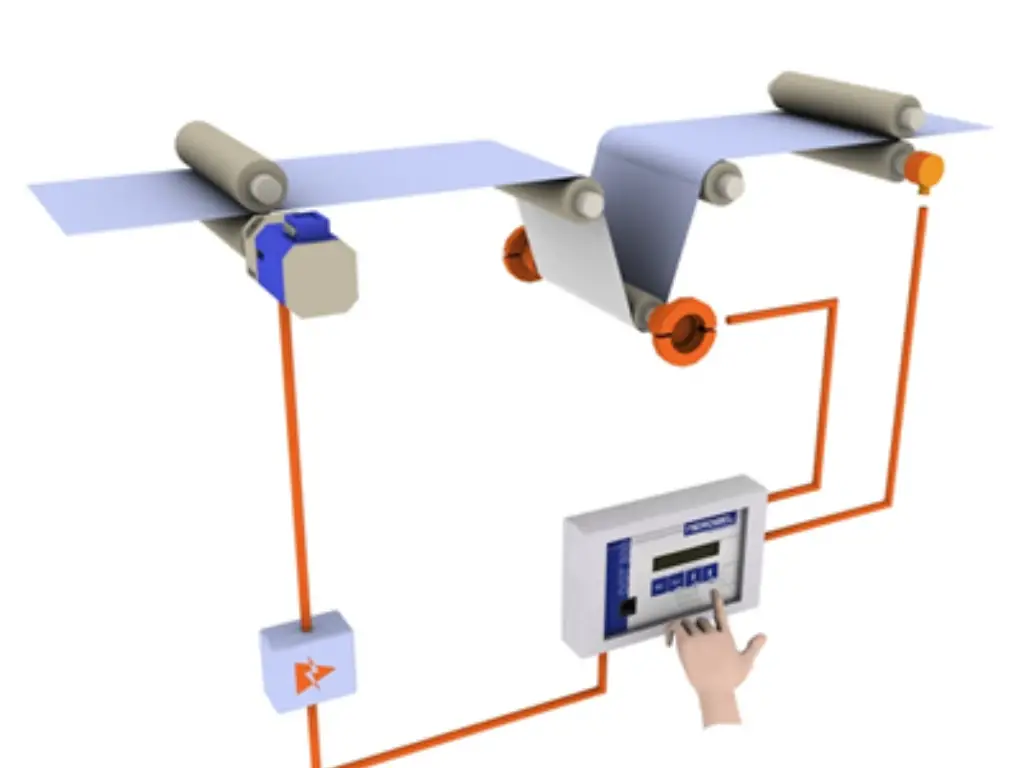

The Tension Control Market is growing steadily as industrial sectors increasingly adopt automated tension management solutions to enhance product quality, operational efficiency, and manufacturing consistency. Tension control systems maintain precise tension levels during processes involving materials such as paper, films, foils, textiles, wires, cables, metals, and printed packaging. These systems ensure smooth unwinding, rewinding, coating, laminating, slitting, and printing operations without wrinkles, stretch, breakage, or misalignment. With rising demand for high-quality flexible packaging, advanced converting machines, and high-speed production lines, tension control solutions have become critical in industrial automation. The market is projected to grow at a CAGR of around 5–7% over the forecast period, driven by technological advancements in web handling, adoption of smart sensors, and increased manufacturing automation across sectors. Integration of tension control with digital monitoring, IoT, and precision drives is transforming traditional production lines into intelligent, efficient, and quality-driven systems.

Market Drivers

Rising demand for flexible and premium packaging in food, pharmaceuticals, and consumer goods is a key driver accelerating the adoption of tension control systems. Increasing automation in manufacturing lines is boosting the need for consistent tension regulation for high-speed and continuous production. Growth in the printing, labeling, and converting industries fuels the requirement for precise web handling and tension accuracy. Advancements in tension controllers, load cells, brakes, and clutches enhance control precision and efficiency. The global expansion of the textile, paper, and metal processing industries supports wider adoption of tension control solutions. Additionally, demand for lightweight and thin packaging materials—susceptible to stretch and breakage—further drives the need for advanced tension control.

Market Challenges

High installation and integration costs for automated tension control systems limit adoption among small and medium-scale manufacturers. System complexity and the need for skilled technicians for calibration and maintenance pose operational challenges. Variations in material thickness, elasticity, and environmental conditions require frequent adjustments, affecting consistency in some applications. Upgrading legacy machines to modern tension control systems can be complicated and costly. Electrical failures, sensor inaccuracies, and downtime caused by malfunctioning tension components can impact production quality and throughput. Additionally, fluctuations in raw material prices—especially metals and specialty films—affect production budgets and investment decisions.

Market Opportunities

The shift toward Industry 4.0 and smart factories provides strong opportunities for IoT-enabled and automated tension control systems. Development of AI-based adaptive tension control systems capable of self-correction and real-time parameter optimization presents innovation potential. Expansion of the flexible packaging industry and sustainable packaging materials opens new avenues for advanced tension technologies. Growth of high-speed digital printing, e-commerce packaging, and specialty films increases market scope. Wireless and cloud-connected tension controllers enabling remote monitoring and predictive maintenance offer new value propositions. Retrofitting solutions for older industrial equipment provide attractive aftermarket opportunities. Collaboration between automation providers, OEMs, and material manufacturers can accelerate development of customized tension control solutions.

Regional Insights

Asia-Pacific dominates the Tension Control Market due to robust manufacturing activity, large packaging and textile production bases, and high growth in electronics and industrial automation across China, India, Japan, and South Korea. China leads with advanced printing, converting, and flexible packaging industries. Europe holds a significant market share driven by high-precision manufacturing, strong adoption of automation, and advanced packaging demand in Germany, Italy, and the UK. North America shows steady growth supported by industrial modernization, e-commerce packaging expansion, and advanced printing technologies in the U.S. and Canada. Latin America, the Middle East, and Africa are gradually adopting tension control systems as manufacturing and packaging infrastructure improve.

Future Outlook

The future of the Tension Control Market will be shaped by digital automation, smart sensors, and self-optimizing control systems. AI-driven and closed-loop tension control solutions will become more widespread, enabling real-time quality correction and material-specific learning. Integration with SCADA, MES, and smart factory platforms will support seamless production monitoring and data-driven decision-making. Energy-efficient and low-maintenance tension components will gain importance as sustainability and cost efficiency rise. Modular and plug-and-play tension systems will simplify upgrades for legacy production lines. As flexible packaging, electric vehicles (for wire and foil winding), and precision manufacturing expand, tension control will continue to play a key role in high-quality production.

Conclusion

The Tension Control Market is evolving as manufacturers prioritize high product quality, fewer defects, and efficient production processes. Tension control systems ensure consistent material handling, making them essential in industries such as packaging, printing, textiles, paper, film, and metal processing. While initial costs, integration complexity, and skill shortages pose challenges, rapid advancements in automation, smart sensors, and digital monitoring are unlocking new opportunities. With rising demand for flexible packaging, high-speed production, and precision processing, the market is positioned for sustained growth. Manufacturers that focus on innovation, smart integration, and low-maintenance tension solutions will gain a competitive edge.