The 1 6 Hexanediol Diacrylate Market stands at the intersection of material innovation and environmental responsibility. Used extensively in UV-curable systems, HDDA offers fast curing, superior hardness, and excellent adhesion. Its versatility across coatings, inks, adhesives, and 3D printing resins makes it indispensable to manufacturers seeking durable and efficient solutions.

Growing industrialization and environmental awareness are driving the adoption of HDDA across various sectors. As industries reduce reliance on solvent-based technologies, HDDA’s low-emission and rapid-curing features make it a sustainable choice. Additionally, the rise in additive manufacturing has opened new avenues for HDDA use in photopolymer resins, enhancing mechanical strength and layer adhesion in printed components.

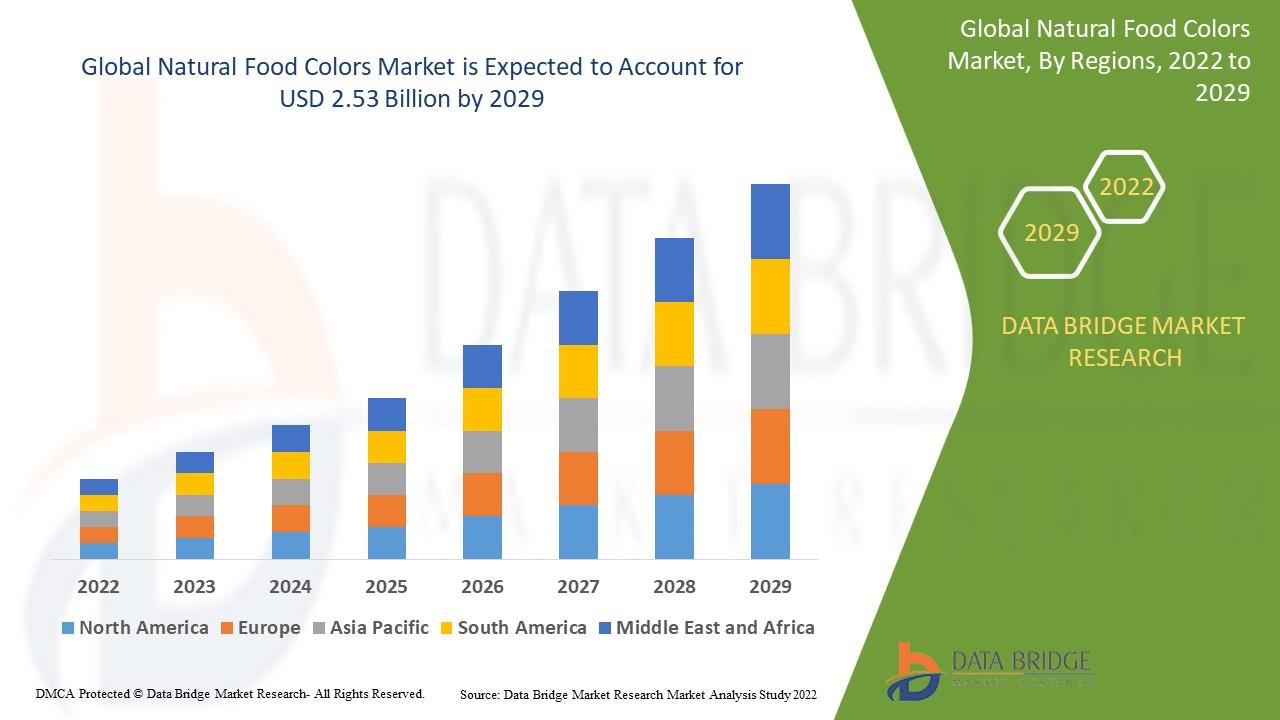

Market trends suggest strong growth potential, particularly in Asia-Pacific, where expanding industrial activities and infrastructure projects create consistent demand. Meanwhile, North America and Europe are focused on innovation-led growth through bio-based and hybrid HDDA formulations.

Recent advances in polymer chemistry and UV-curing systems have set the stage for broader adoption in future-ready materials. The 1 6 Hexanediol Diacrylate Market Trends point toward sustainable innovation, energy efficiency, and greater integration into high-tech manufacturing.

In essence, 1,6-hexanediol diacrylate serves as a vital link in modern material science—bridging high performance with ecological progress. Its evolving applications underscore its importance as industries continue to prioritize efficiency, resilience, and sustainability in the years to come.