The Cable That Keeps Signals Clean

Introduction

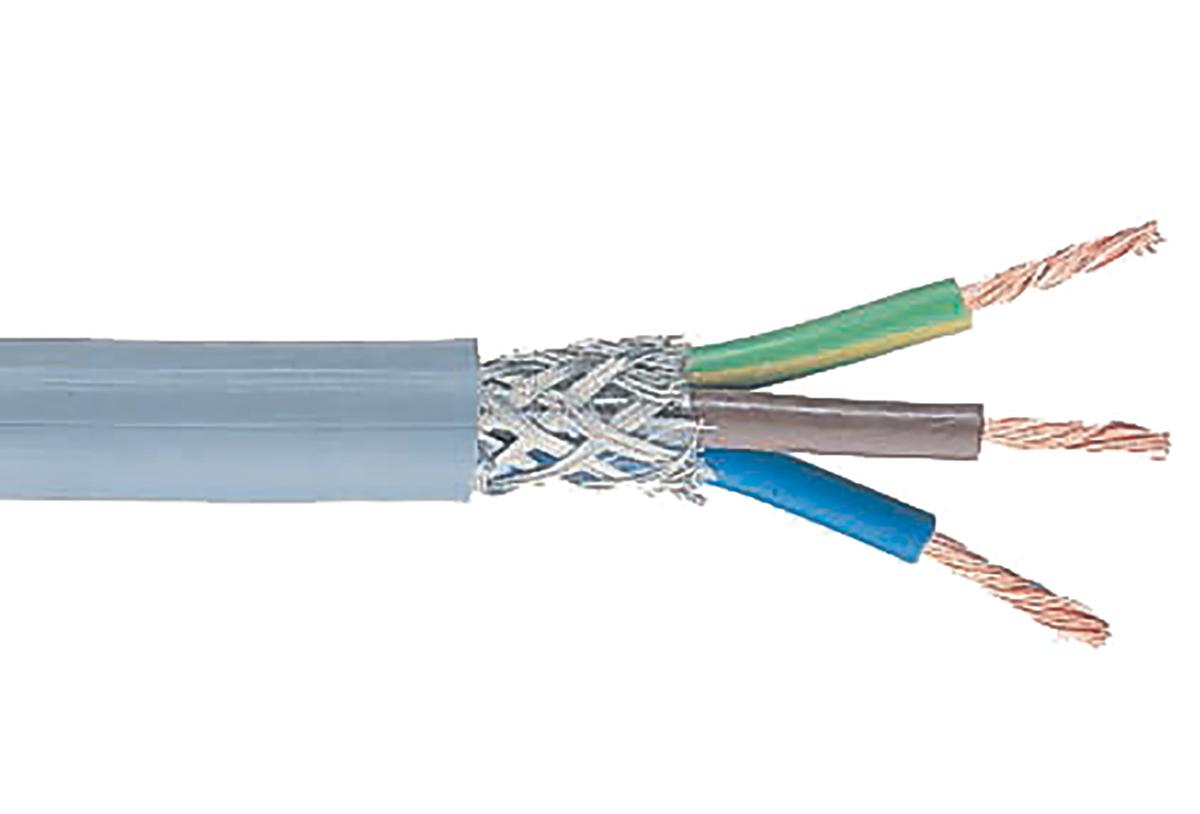

The CY control cable market focuses on specialized screened control cables used in industrial automation, machine tools, production lines, HVAC systems, power distribution panels, and commercial equipment. CY cables are designed with a tinned copper wire braid for electromagnetic interference (EMI) protection, ensuring stable signal transmission and reliable equipment performance. These cables are essential in environments where sensitive control signals must remain unaffected by electrical noise from motors, drives, and high-power machinery. As industries move toward advanced automation, interconnected systems, and precision machinery, the demand for CY control cables continues to grow.

Market Drivers

The market is driven by the rapid expansion of industrial automation and smart manufacturing. Industries such as automotive, food processing, pharmaceuticals, packaging, and electronics rely heavily on accurate control systems, making EMI-protected cables essential. Rising use of variable frequency drives (VFDs), robotics, and automated production lines increases the need for high-quality screened control cables. Commercial HVAC systems and building automation controllers also contribute to market growth. Strict safety and performance requirements in industrial environments push demand for durable, flexible, and interference-resistant cables.

Market Challenges

Despite increasing adoption, the CY control cable market faces certain challenges. Higher cost compared to basic control cables may deter use in cost-sensitive applications. EMI shielding must meet strict standards, and low-quality cables can lead to signal loss, equipment malfunction, or downtime. Installation in harsh environments requires proper bending radius and mechanical protection, adding complexity. The presence of cheaper unshielded alternatives in the market can slow down adoption in certain regions. Additionally, fluctuations in copper prices impact manufacturing costs and market pricing.

Market Opportunities

The market offers significant opportunities with the rise of Industry 4.0, advanced robotics, and smart factory technologies. Demand for precise and reliable signal transmission in automated systems is growing rapidly. The shift toward energy-efficient HVAC and building automation systems increases usage of CY cables in commercial infrastructure. Expansion of renewable energy plants, data centers, and electrical substations creates new application areas requiring EMI-protected control wiring. As developing countries expand their manufacturing base, adoption of high-performance cables is expected to rise. Innovations in insulation materials, fire-resistant designs, and improved shielding enhance product performance and open new market possibilities.

Regional Insights

Demand for CY control cables varies by industrial activity level and automation adoption. Europe holds a strong market share due to high manufacturing standards, widespread industrial automation, and strict EMI regulations in countries such as Germany, France, and the United Kingdom. Asia-Pacific is rapidly expanding as China, India, South Korea, and Southeast Asia increase investments in manufacturing and industrial automation. North America shows consistent demand from automotive, food processing, pharmaceuticals, and HVAC applications in the United States and Canada. The Middle East is growing due to construction, oil and gas automation, and large commercial projects. Latin America and Africa are emerging markets where industrial development is gradually increasing demand.

Future Outlook

The future of the CY control cable market is promising as industries continue to adopt more sophisticated automation technologies. Manufacturers are expected to develop cables with improved flexibility, higher temperature resistance, and enhanced shielding for demanding environments. Digital monitoring systems that detect cable health and predict failures may also influence next-generation cable designs. As global manufacturing shifts toward intelligent and connected systems, CY control cables will remain important for ensuring stable and interference-free control signal transmission.

Conclusion

The CY control cable market plays a critical role in maintaining reliable signal communication in automated and electrically noisy environments. These cables provide essential EMI protection, ensuring smooth operation of industrial machinery, commercial systems, and advanced control equipment. While challenges exist related to cost, installation complexity, and material fluctuations, continuous industrial growth and technological advancement are driving strong demand. As automation becomes central to modern industry, CY control cables will remain a key component of efficient and stable operations.