Global Reciprocating Compressor Market Trends and Outlook

Introduction

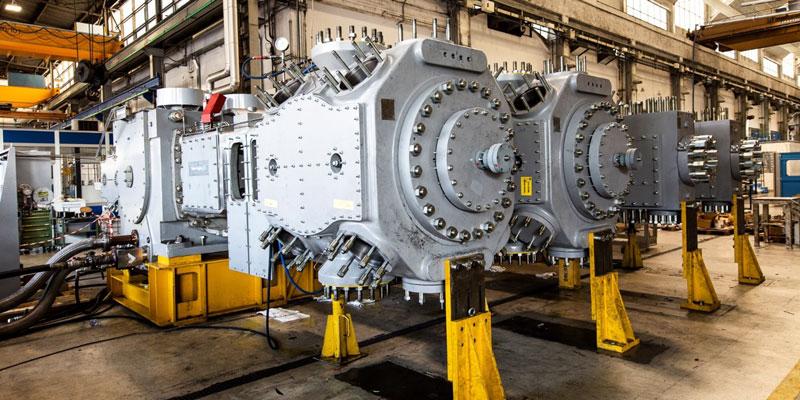

The global reciprocating compressor market is witnessing strong growth as industries increasingly rely on efficient, high-pressure air and gas compression solutions. Reciprocating compressors, also known as piston compressors, are widely used across sectors such as oil & gas, chemical, petrochemical, manufacturing, power generation, and automotive. Their ability to deliver high pressure at variable capacities makes them suitable for critical applications requiring reliability and precision. Rising industrialization, growing energy demand, and the need for efficient gas transportation and storage solutions are driving the market. Additionally, technological advancements in materials, design, and automation are enhancing performance, energy efficiency, and durability, positioning the reciprocating compressor market as a crucial segment within the broader industrial compression industry.

Market Drivers

Several key factors are driving the growth of the reciprocating compressor market. Increasing industrialization and infrastructure development are driving demand for high-capacity air and gas compression systems. The oil & gas industry remains a significant end-user, requiring compressors for gas injection, pipeline transport, and storage operations. Manufacturing and chemical processing industries also rely on reciprocating compressors for pneumatic systems, process gas handling, and other critical applications. Technological advancements, including enhanced piston designs, advanced cooling systems, and smart monitoring, improve efficiency and reduce maintenance costs. Additionally, the rising focus on energy efficiency and reducing operational costs is encouraging the adoption of advanced reciprocating compressor systems.

Market Challenges

Despite the promising growth, the reciprocating compressor market faces several challenges. High initial investment and maintenance costs can limit adoption, particularly among small and medium-sized enterprises. The equipment requires regular inspection, lubrication, and part replacement to maintain optimal performance, which can increase operational complexity. Noise and vibration levels are higher in reciprocating compressors compared to alternative compression technologies, necessitating additional noise control measures. Environmental concerns related to energy consumption and greenhouse gas emissions also present challenges, especially for older models. Furthermore, competition from rotary screw and centrifugal compressors, which offer continuous flow and lower maintenance, can impact market growth in certain applications.

Market Opportunities

The reciprocating compressor market offers significant opportunities for growth and innovation. Development of smart, IoT-enabled compressors allows real-time monitoring, predictive maintenance, and performance optimization, reducing downtime and operational costs. Advances in materials, such as high-strength alloys and composite components, improve durability, reliability, and energy efficiency. Emerging markets in Asia-Pacific, Latin America, and the Middle East are experiencing rapid industrialization and infrastructure development, creating demand for high-capacity compression systems. Additionally, the integration of reciprocating compressors with renewable energy applications, such as hydrogen storage and bio-gas processing, opens new avenues for sustainable solutions. Strategic collaborations, aftermarket services, and product customization further enhance market opportunities.

Regional Insights

Regionally, North America remains a leading market for reciprocating compressors due to advanced industrial infrastructure, widespread adoption of automated manufacturing, and strong oil & gas sector presence. Europe also holds a significant share, driven by strict environmental regulations, energy efficiency mandates, and industrial sophistication. The Asia-Pacific region is emerging as the fastest-growing market, fueled by industrial expansion, infrastructure development, and increasing energy demand in countries like China, India, Japan, and South Korea. Latin America and the Middle East & Africa are witnessing moderate growth, primarily driven by oil & gas, mining, and construction industries. Regional growth dynamics are influenced by local industrial policies, energy regulations, and investments in technological modernization.

Future Outlook

The reciprocating compressor market is expected to maintain steady growth in the coming years. Technological innovations in energy efficiency, smart monitoring, and predictive maintenance will enhance equipment performance and reliability. Adoption of automated and digitally integrated systems will improve operational efficiency, reduce downtime, and lower maintenance costs. Environmental sustainability will continue to be a key driver, with increasing demand for low-emission, energy-efficient compressors. Emerging markets will provide significant growth opportunities, while mature markets will focus on upgrading existing infrastructure with advanced systems. Overall, the market is poised for technological transformation, global expansion, and sustainability-driven adoption, solidifying its role in industrial operations worldwide.

Conclusion

Reciprocating compressors are essential for industrial applications requiring high pressure, reliability, and precision. The market is growing due to industrial expansion, technological advancements, and demand for energy-efficient solutions. Challenges such as high initial costs, maintenance requirements, and noise concerns exist, but opportunities in smart technologies, advanced materials, and emerging markets provide significant growth potential. North America and Europe lead in technology adoption, while Asia-Pacific represents a rapidly expanding market. With continued innovation and increasing focus on sustainability, reciprocating compressors will remain critical to global industrial and energy operations.