From Dairy to Biologics: Where the Aseptic Filling Machine Market Is Growing Fastest

Modern consumers want products that are safe, convenient, and long-lasting. From shelf-stable milk and fruit juices to injectable medicines and biotech solutions, the need for contamination-free filling has become a top priority for manufacturers. This shift has placed aseptic filling machines at the center of global packaging and processing investments. Aseptic technology allows liquids and semi-liquids to be filled into sterile containers in a sterile environment, helping products achieve longer shelf life without refrigeration or preservatives.

According to Market Research Future, the aseptic filling machine industry is witnessing consistent expansion as global industries move toward high-efficiency, hygienic, and automated production systems. The Aseptic Filling Machine Market is being strengthened by rising packaged food consumption, pharmaceutical production growth, and stricter quality regulations worldwide. Companies are investing heavily in aseptic filling lines to reduce contamination risks, increase throughput, and improve product stability.

A key driver behind this market is the rising demand for shelf-stable beverages and dairy alternatives. Consumers are increasingly purchasing ready-to-drink beverages such as flavored milk, plant-based drinks, energy beverages, and fruit juices. These products require extended shelf life while maintaining taste, nutrients, and freshness. Aseptic filling machines enable manufacturers to meet these expectations by ensuring the product remains free from microbial contamination during filling and sealing.

The pharmaceutical and healthcare industries are also major contributors to market growth. Sterile filling is essential for injectable drugs, vaccines, IV fluids, ophthalmic solutions, and biologics. Even small contamination levels can cause serious health risks and product recalls. As global pharmaceutical output rises, especially in emerging economies, aseptic filling machines are becoming essential for meeting compliance requirements and production standards.

Another major market influence is automation. Traditional filling systems can require significant manual oversight, but modern aseptic machines integrate sensors, robotics, and digital monitoring. This reduces human contact with sterile zones, lowering contamination risks while improving efficiency. Automated aseptic filling systems also support higher production speeds, which is critical for companies scaling their operations.

Packaging evolution is another factor boosting the market. Aseptic filling is not limited to cartons. It is now widely used for plastic bottles, pouches, bags-in-box, ampoules, vials, syringes, and glass containers. This versatility allows manufacturers to offer new product formats while maintaining sterile conditions. Flexible packaging growth in food and beverage markets has further increased demand for aseptic filling solutions.

A major indicator shaping the industry is Aseptic Filling Machine Demand, which continues to rise due to expanding global production capacity and increasing quality regulations. Demand is especially strong among beverage companies, dairy processors, and pharmaceutical manufacturers who want consistent sterility and high-speed output.

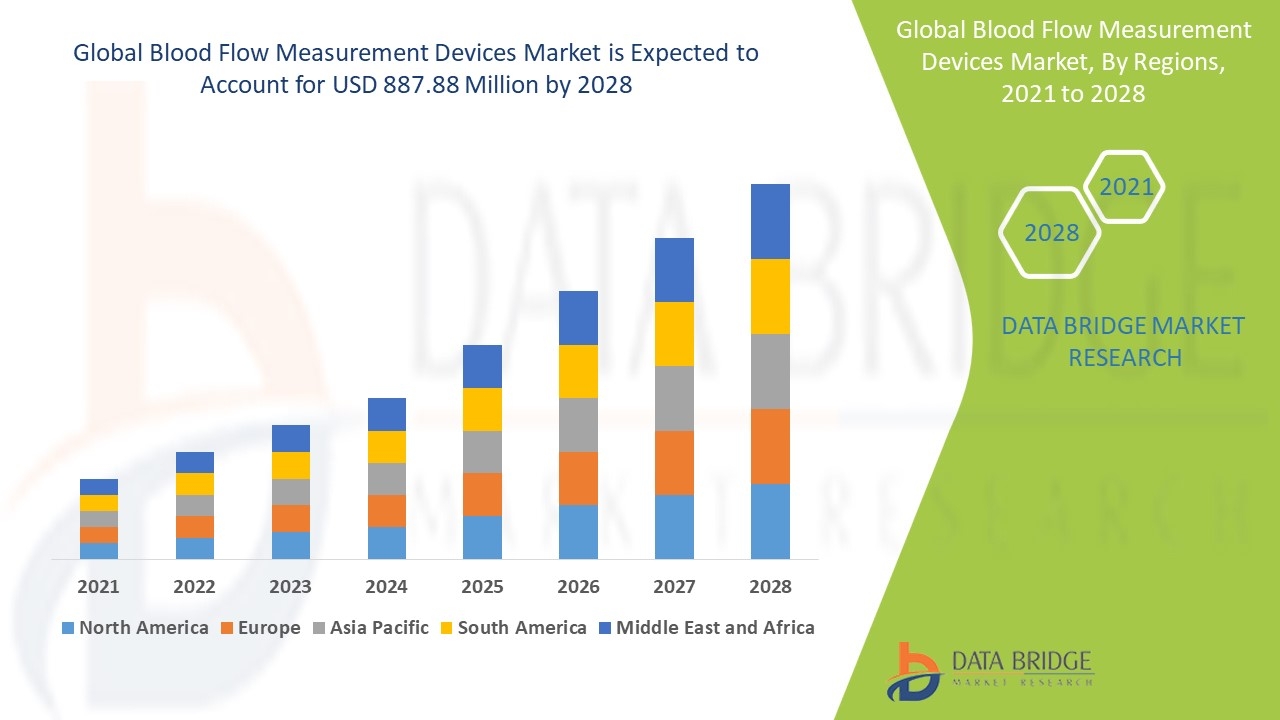

From a regional perspective, Asia-Pacific remains a high-growth market due to expanding packaged food consumption, rising healthcare spending, and increased investment in industrial automation. North America remains strong due to advanced pharmaceutical manufacturing and strict regulatory standards. Europe continues to lead in aseptic processing technology adoption due to established food and beverage brands and robust healthcare infrastructure.

Despite strong growth, the market faces challenges. Aseptic filling machines require high upfront investment, which can be a barrier for small and mid-sized manufacturers. The systems also require specialized maintenance, skilled operators, and strict validation procedures. Any error in sterilization or process control can result in contamination risks, production downtime, or regulatory compliance issues.

However, manufacturers are responding with modular systems, improved CIP/SIP capabilities (clean-in-place and sterilize-in-place), and more user-friendly control systems. These advancements are making aseptic filling technology more accessible, scalable, and reliable.

In conclusion, the aseptic filling machine market is growing steadily as industries prioritize hygiene, shelf stability, automation, and compliance. With continued innovation in packaging formats, smart manufacturing, and sterile processing, aseptic filling machines are expected to remain a critical investment area for food, beverage, and pharmaceutical manufacturers worldwide.