US Automotive Engine Encapsulation Market: Redefining Efficiency and Comfort

Introduction

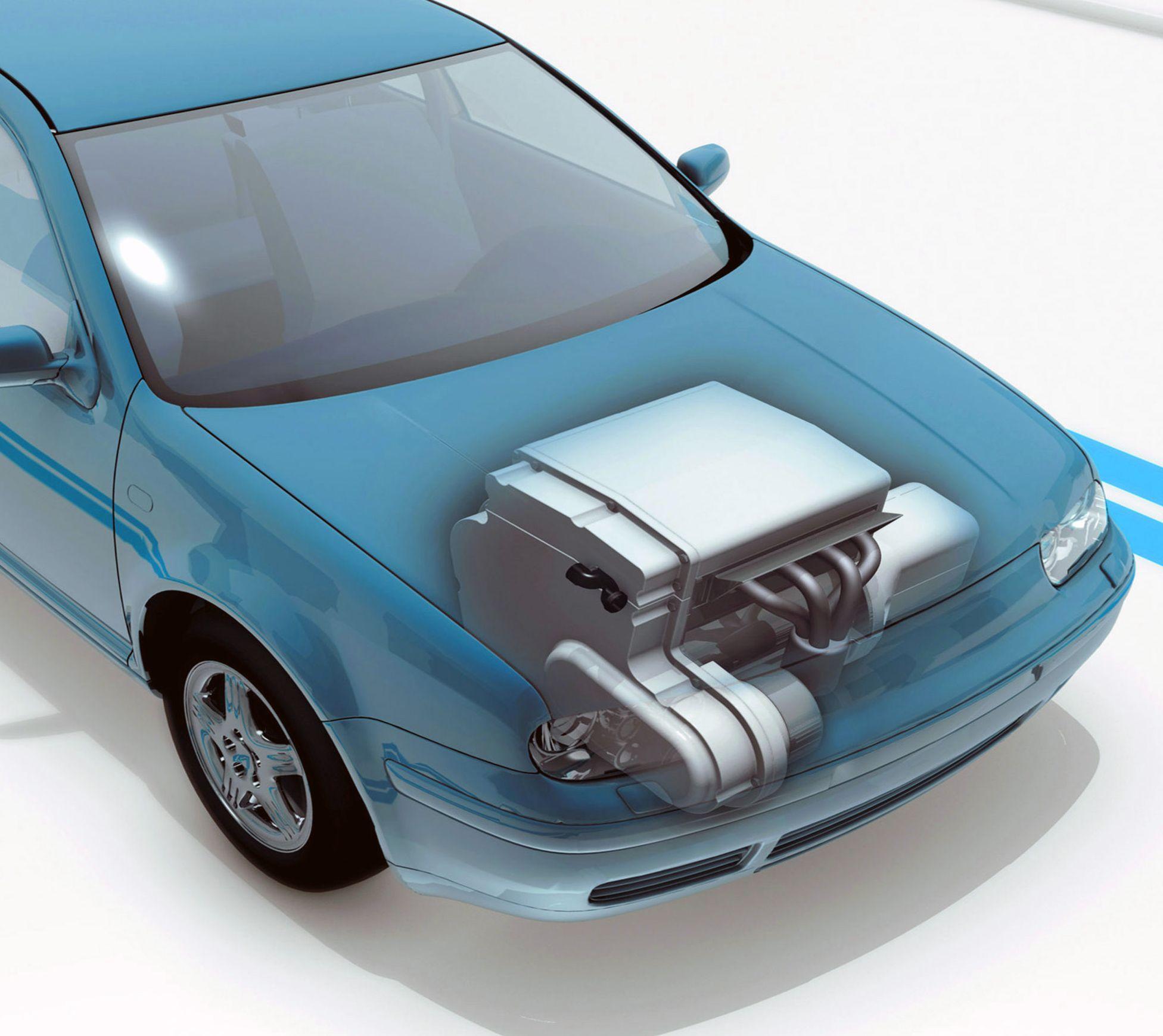

The US Automotive Engine Encapsulation Market is gaining traction as automakers prioritize efficiency, performance, and sustainability in modern vehicle design. Engine encapsulation involves using thermoplastic or composite panels around the engine compartment to maintain optimal operating temperatures and reduce noise emissions. In the United States, where fuel economy standards and environmental regulations are stringent, this technology has become an essential component in both internal combustion engine (ICE) and hybrid vehicles. Beyond thermal management, encapsulation also contributes to reduced CO₂ emissions, faster engine warm-up, and improved cabin acoustics. As the automotive industry continues its transformation toward lightweight materials and energy-efficient solutions, engine encapsulation is emerging as a strategic innovation driving next-generation vehicle engineering.

Market Drivers

A major driver of the US automotive engine encapsulation market is the rising emphasis on fuel efficiency and emission control. By maintaining optimal engine temperatures, encapsulation reduces friction losses during cold starts, leading to lower fuel consumption. Additionally, government initiatives promoting environmental sustainability—such as the Corporate Average Fuel Economy (CAFE) standards—are pushing automakers to adopt advanced thermal insulation technologies. The demand for premium and luxury vehicles with superior NVH (Noise, Vibration, and Harshness) performance further propels market growth. Lightweight materials like polypropylene, polyurethane, and carbon-fiber composites are being increasingly used to design encapsulation systems that enhance both efficiency and vehicle aesthetics. Moreover, growing hybrid and EV adoption is boosting interest in encapsulation solutions for better temperature and sound management.

Market Challenges

Despite its advantages, the market faces several challenges related to design complexity, material cost, and thermal durability. The integration of encapsulation systems requires precise engineering to balance heat retention with adequate ventilation. Excessive insulation can risk overheating or reduce component lifespan, especially in high-performance engines. The cost of high-grade materials and production processes can be a limiting factor for mass-market vehicle segments. Additionally, retrofitting encapsulation into existing models is technically challenging due to space constraints and varying engine configurations. Environmental concerns regarding the recyclability of polymer-based encapsulation materials also pose long-term sustainability challenges. To overcome these issues, manufacturers must focus on optimizing designs and developing advanced, eco-friendly materials that deliver both performance and affordability.

Market Opportunities

The US automotive engine encapsulation market offers significant opportunities in advanced material innovation and hybrid vehicle applications. The shift toward electric and plug-in hybrid vehicles introduces demand for new thermal management systems that protect batteries and power electronics. Companies investing in lightweight, high-temperature-resistant composites can gain a competitive edge. Integration of smart materials and active thermal management technologies—such as phase-change materials (PCMs) and intelligent sensors—represents a growing opportunity for R&D. Collaborations between OEMs and material suppliers are fostering customized encapsulation designs tailored to specific vehicle architectures. Moreover, the focus on acoustic comfort and noise suppression in urban mobility vehicles opens avenues for combining thermal and sound insulation in unified encapsulation solutions.

Regional Insights

The United States demonstrates a strong regional adoption pattern, with states such as Michigan, Ohio, and California leading the market due to their concentration of OEMs, research centers, and automotive suppliers. The Midwest region continues to dominate manufacturing activity, particularly in ICE and hybrid vehicle components, while California leads in EV and sustainable vehicle innovation. Southern states like Texas and Tennessee, hosting major automotive assembly plants, are experiencing increased demand for lightweight, thermally efficient encapsulation components. Regional growth is also supported by ongoing investments in R&D and the presence of material science companies specializing in thermal and acoustic insulation. With the US automotive sector emphasizing both environmental compliance and performance excellence, regional dynamics continue to strengthen market expansion.

Future Outlook

The future of the US Automotive Engine Encapsulation Market looks promising as vehicle electrification and sustainability trends accelerate. Over the coming decade, encapsulation technology is expected to evolve from passive thermal protection to intelligent, active systems capable of regulating temperature dynamically. The introduction of recyclable and bio-based materials will align with circular economy goals, reducing environmental impact. EV manufacturers will increasingly leverage encapsulation for battery thermal management, sound insulation, and component protection. Continuous R&D in aerodynamics and lightweight design will further enhance system integration. As fuel efficiency, comfort, and eco-design become central to automotive innovation, engine encapsulation will play a pivotal role in achieving performance and regulatory milestones across the US vehicle landscape.

Conclusion

The US Automotive Engine Encapsulation Market represents a critical advancement in modern vehicle engineering—merging efficiency, sustainability, and comfort into a single solution. By improving thermal performance, reducing emissions, and enhancing acoustic experience, engine encapsulation supports automakers’ goals of achieving greener and quieter vehicles. While challenges in cost and design persist, material innovation and intelligent thermal management are paving the way for broader adoption. As the automotive industry transitions toward electrified and sustainable mobility, engine encapsulation will remain an indispensable technology shaping the next era of efficient and environmentally conscious vehicle design in the United States.