Global Cold Cast Elastomers Market Poised for Resilient Growth, Set to Reach $1.88 Billion by 2032 Driven by Automotive and Aerospace Demand..

Introspective Market Research, a global authority in market intelligence, today released a comprehensive report on the Cold Cast Elastomers Market. The research highlights the market’s steady and vital expansion, propelled by the surging global requirement for high-performance, lightweight, and durable materials, particularly within the automotive, aviation, and oil & gas sectors.

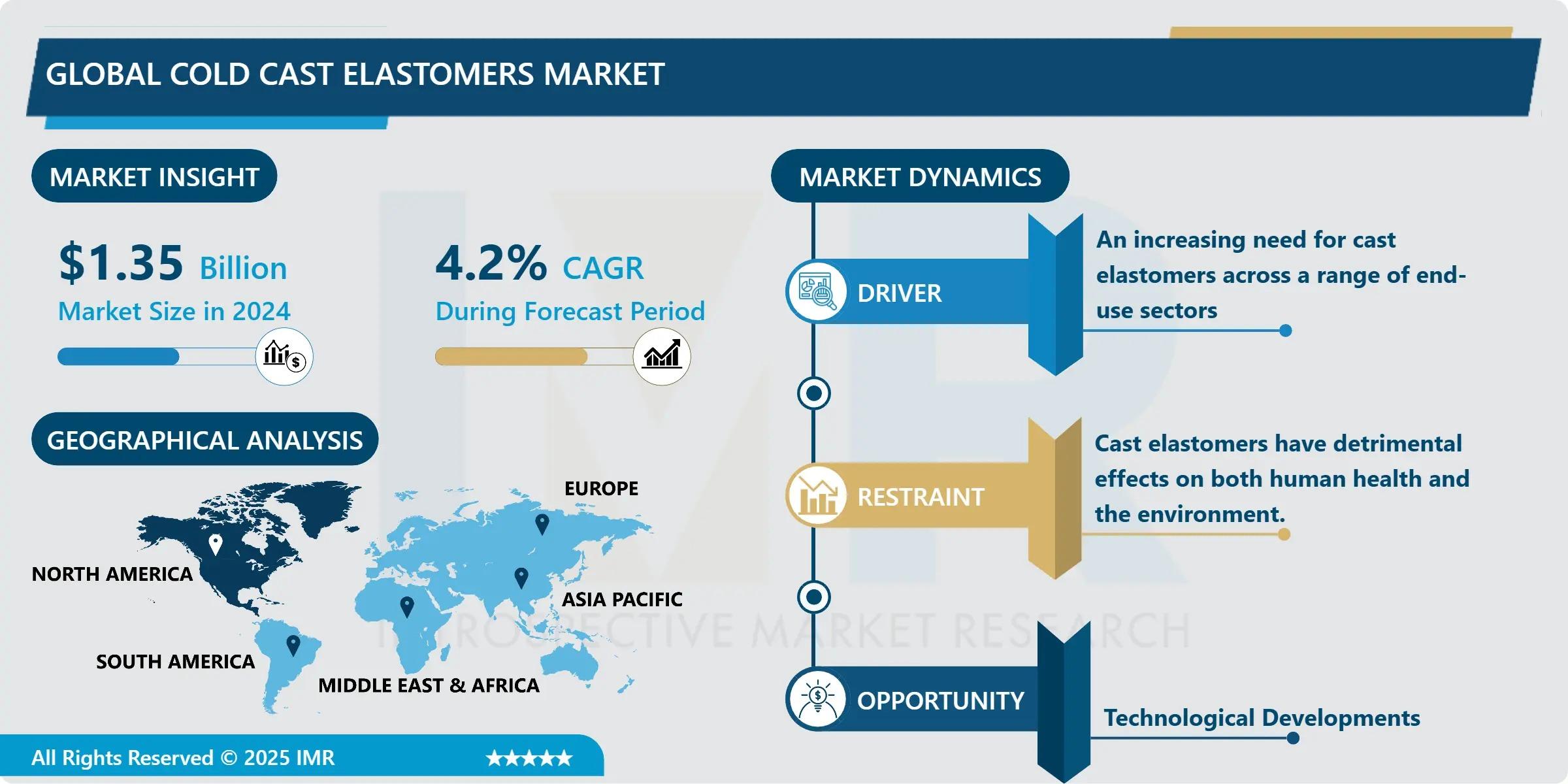

Cold cast elastomers, characterized by their ability to achieve rubber-like flexibility, resilience, and strength without the need for high-temperature curing, are rapidly becoming indispensable across multiple industrial applications. The market, valued at USD 1.35 Billion in 2024, is firmly on track to achieve a valuation of USD 1.88 Billion by 2032, reflecting a robust Compound Annual Growth Rate (CAGR) of 4.2% throughout the forecast period (2025–2032). This consistent upward trend is fundamentally driven by the accelerating need for superior material solutions across a wide range of end-use sectors.

Quick Market Insights:

A summary of the key findings from the global Cold Cast Elastomers Market report:

-

Market Valuation: The market is projected to expand significantly, targeting a valuation of USD 1.88 Billion by 2032.

-

Growth Driver: The primary impetus is the increasing global demand for lightweight and high-performance materials that offer exceptional flexibility, durability, and chemical resistance.

-

Dominant Type Segment: The Three Component elastomer systems are expected to dominate the market due to their enhanced flexibility, superior mechanical properties, and adaptability to complex industrial requirements.

-

Leading Application: The Automotive segment currently holds the largest market share, leveraging the materials for gaskets, seals, vibration dampers, and parts crucial for vehicle lightweighting efforts.

-

Regional Dominance: North America is forecast to dominate the market, supported by strong technological advancements and a high demand from its mature automotive, aerospace, and oil & gas industries.

-

Competitive Landscape: Key industry leaders include BASF, DowDuPont, Covestro, and Huntsman International, who are focusing heavily on advanced formulation development and strategic acquisitions.

Revenue Breakdown and Market Dynamics (2025–2032)

|

Metric |

Base Year (2024) |

Forecasted Value (2032) |

CAGR (2025–2032) |

|---|---|---|---|

|

Market Size (USD) |

1.35 Billion |

1.88 Billion |

4.2% |

The versatility of cold cast elastomers allows manufacturers to customize material features to meet dissimilar functional needs, from high-pressure sealing apparatus in the oil and gas industry to weight-reducing components in aviation. This adaptability and consistency make them a highly sought-after alternative to traditional rubber and engineered plastics.

How Will Technological Developments Shape the Future Opportunities in the Cold Cast Elastomers Market?

Technological advancements are the primary fuel for future market growth. The focus is currently on sophisticated research and development (R&D) efforts aimed at formulating new elastomer systems that offer superior chemical resistance, higher temperature stability, and better mechanical strength. These innovations, particularly in three-component systems, allow for precise tuning of material properties, opening up new frontiers in electronics, medical devices, and specialized construction applications.

Furthermore, innovations in efficient production strategies are bolstering market competitiveness. As industries intensify their pursuit of materials that offer optimal performance, durability, and cost-effectiveness, the trend towards high-tech, functional, and varied elastomer solutions is set to accelerate market expansion across previously untapped industrial applications.

Expert Commentary on Market Trajectory

“The Cold Cast Elastomers market is fundamentally driven by the need for materials that can deliver in extreme conditions—whether that’s resistance to harsh chemicals in the oil and gas sector or the demand for lightweight durability in modern aircraft,” says Dr. Elara Vance, Principal Consultant at Introspective Market Research. “While the market must address lingering concerns regarding environmental impact and certain health concerns associated with some raw materials, the opportunity presented by new technological developments is immense. North American dominance, particularly, is secured by its high pace of industrial innovation and strict performance mandates in its largest end-use sectors.”

Regional and Segmentation Analysis

North America is expected to lead the market throughout the forecast period, primarily due to its strong R&D infrastructure and the substantial, established demand for customized elastomer solutions from its advanced automotive, aerospace, and energy industries. Strict regional environmental and performance standards also favor the adoption of high-quality, cold-cast formulations.

Segmentation by Type: The Three Component system is projected to be the dominant type. These systems offer greater control over the final product's characteristics—such as flexibility and mechanical toughness—making them highly attractive for high-specification industrial and engineering applications.

Segmentation by Application: The Automotive sector remains the largest application segment. The consistent industry trend of vehicle lightweighting to improve fuel efficiency and meet stringent emission regulations guarantees sustained high demand for these materials in essential parts like seals and vibration damping elements.

Latest Breakthroughs and Competitive Edge

Major market players are continuously strengthening their competitive positions through strategic development and portfolio expansion:

-

BASF is driving the industry toward sustainability, as evidenced by its expansion of certified compostable biopolymers, introducing a biomass-balanced (BMB) ecoflex® in January 2024. This innovation signals a strong commitment to replacing fossil-based raw materials with renewable feedstocks, addressing environmental concerns directly.

-

DowDuPont is strategically enhancing its presence in high-value, regulated markets. Its acquisition of Donatelle Plastics in July 2024, a specialized medical device company, integrates advanced manufacturing capabilities, positioning DowDuPont strongly within the demanding healthcare component sector that requires extremely high-purity elastomer products.

-

Covestro and Huntsman International continue to focus on creating specialized elastomer formulations that offer superior resistance to wear and tear, catering to the challenging operational environments found in mining and heavy industrial machinery.

Addressing Health and Environmental Concerns for Market Efficiency

The core challenge for continued, sustainable market growth involves addressing the known detrimental effects of some traditional cast elastomer materials on human health and the environment. To make the product truly cost-efficient and ensure long-term market viability, manufacturers must focus on:

-

Sustainable Formulations: Investing heavily in R&D to replace hazardous fossil-fuel derived components with bio-based or recycled content, as demonstrated by industry leaders like BASF.

-

Closed-Loop Manufacturing: Developing recycling and repurposing streams for end-of-life elastomer products to reduce environmental waste and reliance on virgin raw materials, thereby lowering long-term production costs.

-

Process Optimization: Implementing advanced mixing and casting techniques that minimize material waste and improve cure times, enhancing overall production efficiency and reducing the cost per unit.

Key Benefits of Cold Cast Elastomers:

-

Superior Durability and Flexibility: Exhibits excellent mechanical properties similar to rubber without needing heat curing.

-

Chemical and Abrasion Resistance: Ideal for harsh industrial environments, extending product lifespan.

-

Weight Reduction: Crucial for applications in automotive and aerospace, contributing to fuel efficiency.

-

Customization: Formulas are easily tailored (especially three-component systems) to meet specific application requirements.

Request the Full Market Report

The comprehensive 240+ page report provides a detailed, granular analysis of market share by manufacturer, competitive benchmarking, detailed regional breakdowns, and strategic insights for navigating key opportunities and environmental challenges.

Download Sample / Request Demo

About Introspective Market Research

Introspective Market Research is a visionary and independent market research company, providing clients with customized and syndicated market research reports that offer a complete analysis of current and future business opportunities. We provide insights into emerging trends, consumer behavior, and competitive landscapes across various industries to help organizations make informed strategic decisions.

Contact Information: Introspective Market Research

Contactb Us:-+91-91753-37569