Global Outlook of the Electricity & Steam Generation Waste Heat Recovery System Market

Introduction

The electricity & steam generation waste heat recovery system market is a critical segment of the global energy efficiency and industrial sustainability industry, focused on converting unused thermal energy into usable electricity or steam. Waste heat recovery systems capture excess heat from industrial processes, power plants, refineries, cement kilns, steel furnaces, and gas turbines that would otherwise be lost to the environment. This recovered energy is then reused for power generation, steam production, or process heating, significantly improving overall system efficiency. With rising energy costs, tightening emission regulations, and strong global emphasis on decarbonization, industries are increasingly adopting waste heat recovery solutions to reduce fuel consumption and carbon footprint. Governments and utilities are also promoting waste-to-energy technologies to enhance energy security and reduce dependence on fossil fuels, positioning this market as a key component of the global transition toward sustainable energy systems.

Market Drivers

One of the primary drivers of the electricity & steam generation waste heat recovery system market is the increasing emphasis on energy efficiency across industrial and power generation sectors. Industries such as cement, steel, chemicals, glass, and oil & gas generate large quantities of high-temperature waste heat, creating a strong economic incentive to recover and reuse this energy. Rising global fuel prices are pushing operators to maximize internal energy utilization and reduce operating costs through heat recovery systems. Stringent environmental regulations aimed at reducing greenhouse gas emissions and industrial pollution are compelling companies to adopt energy-efficient technologies. Rapid industrialization and expanding manufacturing capacity in emerging economies are further increasing demand for waste heat recovery installations. Government incentives, energy efficiency mandates, and carbon reduction targets are also encouraging investments in both retrofitting existing plants and integrating recovery systems into new industrial facilities. Additionally, the growing focus on cogeneration and combined heat and power systems is strengthening demand for integrated heat recovery technologies.

Market Challenges

Despite strong demand fundamentals, the electricity & steam generation waste heat recovery system market faces several challenges. High initial capital investment required for system design, installation, and integration with existing infrastructure remains a major barrier, especially for small and medium-sized enterprises. The performance of waste heat recovery systems is highly dependent on process temperature, heat availability, and operational stability, limiting feasibility in low-temperature or intermittent processes. Complex system integration and space constraints in older plants can increase project costs and technical complexity. Maintenance requirements for heat exchangers, turbines, and control systems add to long-term operating expenses. Inadequate technical expertise and lack of awareness in certain developing regions can slow adoption. The market is also influenced by fluctuations in industrial output and capital expenditure cycles, as economic downturns often delay large energy efficiency projects.

Market Opportunities

The market offers significant growth opportunities through advancements in heat recovery technologies and rising adoption of low-carbon power generation systems. Emerging solutions such as organic Rankine cycle systems and supercritical CO₂ cycles are expanding the scope of electricity generation from low- and medium-temperature waste heat. Growing investments in hydrogen production, data centers, and renewable-integrated industrial plants are creating new applications for steam and power recovery systems. Emerging markets in Asia-Pacific, Latin America, and Africa present substantial growth potential due to expanding industrial bases and rising energy demand. Retrofitting aging industrial plants with modern waste heat recovery systems offers strong aftermarket opportunities. Integration of digital monitoring, automation, and predictive maintenance is improving system reliability and performance optimization. The growing push for net-zero manufacturing, smart factories, and circular economy models is further strengthening demand for waste heat recovery solutions.

Regional Insights

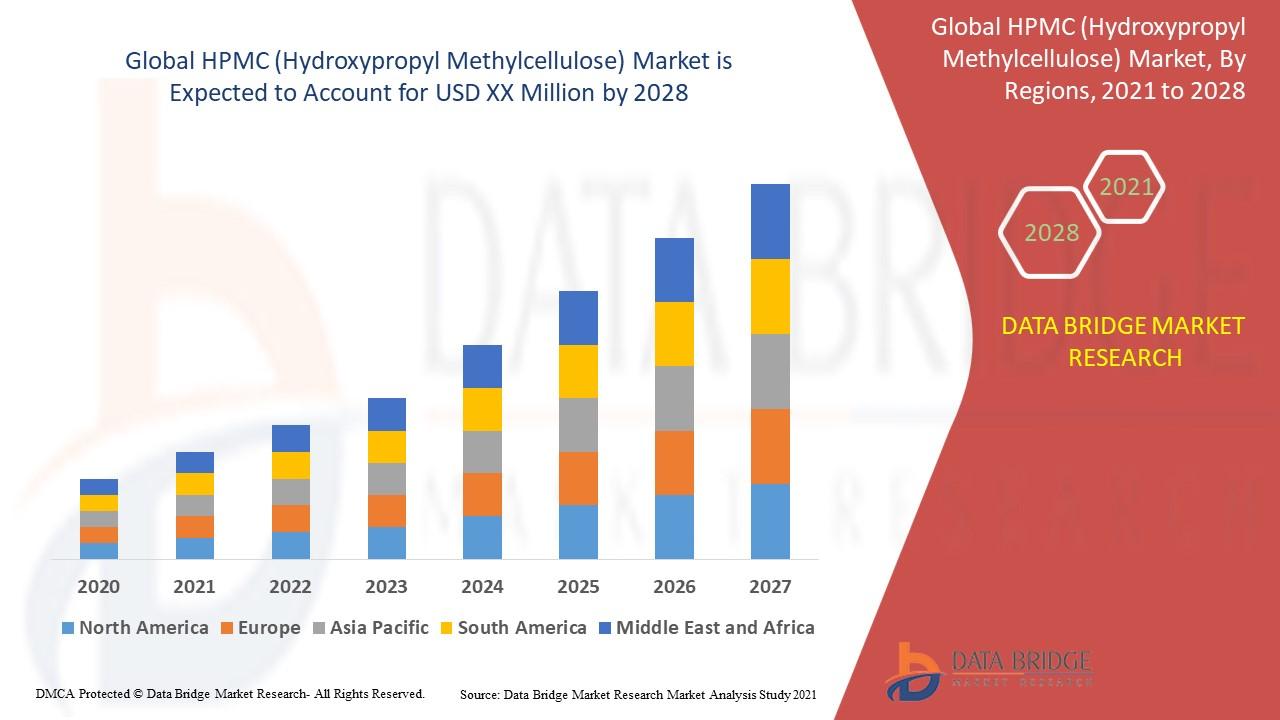

Asia-Pacific dominates the electricity & steam generation waste heat recovery system market due to rapid industrialization, large-scale power generation capacity, and strong government support for energy efficiency projects in China, India, Japan, and Southeast Asia. China leads global installations with widespread deployment of waste heat recovery in cement, steel, and chemical industries. India is emerging as a high-growth market driven by industrial expansion and national energy efficiency programs. Europe represents a mature market supported by strict emission regulations, advanced industrial automation, and strong adoption of combined heat and power systems. Germany, Italy, and the Nordic countries are key contributors in the region. North America holds a significant share driven by refinery modernization, power plant efficiency upgrades, and growing focus on industrial decarbonization in the United States and Canada. Latin America is an emerging market supported by cement, mining, and refinery projects in Brazil, Mexico, and Chile. The Middle East & Africa region is gradually expanding due to investments in power generation, petrochemicals, and energy-intensive industries.

Future Outlook

The future of the electricity & steam generation waste heat recovery system market will be shaped by global decarbonization goals, rising energy efficiency standards, and industrial digital transformation. Adoption of advanced power cycles, high-performance heat exchangers, and intelligent control systems will improve thermal-to-electric conversion efficiency. Integration of waste heat recovery with renewable energy, hydrogen production, and energy storage systems will enable hybrid low-carbon power generation platforms. Smart monitoring, artificial intelligence-based optimization, and remote diagnostics will reduce downtime and improve lifecycle performance. As industrial sectors move toward net-zero targets, waste heat utilization will become a standard requirement in new plant designs and major retrofits. Growing investments in smart manufacturing, data centers, and sustainable infrastructure will further expand application areas. Over the long term, waste heat recovery is expected to remain a cornerstone technology for reducing industrial energy losses and enhancing system-wide energy efficiency.

Conclusion

The electricity & steam generation waste heat recovery system market is a strategic enabler of energy efficiency, cost reduction, and emissions control across industrial and power generation sectors. Market growth is being driven by rising energy prices, strict environmental regulations, rapid industrial expansion, and strong global focus on sustainable manufacturing. While challenges such as high capital investment, technical integration complexity, and dependence on industrial operating conditions persist, continuous technological innovation and expanding retrofit opportunities are strengthening long-term market prospects. Asia-Pacific remains the dominant growth engine, while Europe and North America lead in regulatory-driven adoption and advanced system integration. As global industries accelerate their transition toward low-carbon and energy-efficient operations, waste heat recovery systems will continue to play a vital role in enabling sustainable electricity and steam generation worldwide.