Global Outlook of the C Wrap Labelling Machine Market

Introduction

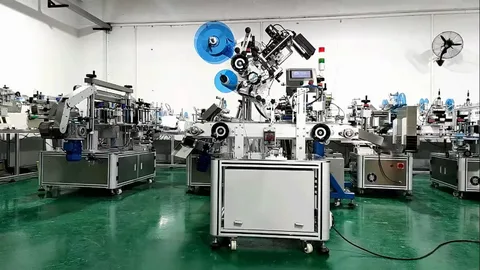

The C wrap labelling machine market is an important segment of the global packaging machinery industry, focused on equipment designed to apply C-shaped labels around the front, side, and back surfaces of products or cartons. These machines are widely used in food and beverage, pharmaceuticals, personal care, household goods, and logistics sectors where brand visibility, product identification, and regulatory compliance are critical. C wrap labelling offers high aesthetic appeal, strong adhesion, and space-efficient label placement, making it suitable for both primary and secondary packaging applications. With rising demand for packaged and processed goods across urban and semi-urban regions, manufacturers are increasingly investing in automated and high-speed C wrap labelling solutions to enhance productivity and ensure consistent output quality. The growing focus on product traceability, marketing differentiation, and operational efficiency is positioning C wrap labelling machines as a vital component of modern automated packaging lines.

Market Drivers

One of the primary drivers of the C wrap labelling machine market is the rapid expansion of the packaged food and beverage industry worldwide. Increasing consumption of ready-to-eat foods, beverages, and convenience products is driving demand for high-speed, accurate, and hygienic labelling systems. Growth in the pharmaceutical and healthcare sectors is also significantly boosting adoption, as strict labeling regulations require precise placement of barcodes, dosage information, and safety details. Rising labor costs and the need for consistent output quality are pushing manufacturers toward fully automated labelling systems. The growth of e-commerce and modern retail formats is further strengthening the need for attractive, durable, and informative product labels. Technological advancements in servo motors, vision inspection systems, and programmable logic controllers are improving machine speed, accuracy, and flexibility. In addition, increasing demand for customized packaging and short production runs is encouraging the adoption of versatile C wrap labelling machines capable of quick changeovers.

Market Challenges

Despite favorable growth conditions, the C wrap labelling machine market faces several challenges. High initial investment costs for advanced automated machines can be a barrier for small and medium-sized manufacturers. Integration of new labelling machines into existing packaging lines may require additional modifications, increasing overall project costs and installation time. Machine performance is highly dependent on label material quality, adhesive properties, and environmental conditions such as humidity and temperature, which can affect output consistency. Maintenance of high-speed mechanical components, sensors, and control systems adds to long-term operational expenses. The market is also affected by supply chain disruptions for automation components, electronic parts, and precision mechanical assemblies. In developing regions, limited availability of skilled technicians for machine operation and troubleshooting can hinder effective utilization. Additionally, fluctuating demand across end-use industries can create short-term volatility in machine sales.

Market Opportunities

The C wrap labelling machine market presents strong growth opportunities through automation, digitalization, and the expansion of emerging manufacturing sectors. Rising adoption of Industry 4.0 concepts is driving demand for smart labelling machines with real-time monitoring, predictive maintenance, and remote diagnostics. The continuous expansion of pharmaceutical manufacturing, especially in emerging economies, is creating long-term opportunities for high-precision C wrap labelling equipment. Growth in sustainable packaging is encouraging the use of recyclable labels and bio-based adhesives, opening new compatibility and innovation opportunities for machine manufacturers. Asia-Pacific, Latin America, and Africa offer strong untapped potential due to rising processed food consumption and increasing establishment of modern production facilities. The aftermarket segment also offers stable revenue through spare parts, servicing, upgrades, and retrofitting of older machinery. Customization of machines to support multiple container shapes and rapidly changing product designs is another key opportunity for equipment suppliers.

Regional Insights

Asia-Pacific dominates the C wrap labelling machine market due to rapid industrialization, expanding food processing capacity, and strong growth in pharmaceutical manufacturing across China, India, Japan, and Southeast Asia. China leads the region with large-scale packaging machinery production and high domestic demand from consumer goods manufacturers. India is emerging as a high-growth market driven by food processing sector expansion and increasing pharmaceutical exports. Europe represents a mature but technologically advanced market supported by strict packaging regulations, strong focus on automation, and presence of leading machine manufacturers in Germany, Italy, and France. North America holds a significant market share due to high adoption of automated packaging lines in food, beverage, and healthcare industries in the United States and Canada. Latin America is an emerging market supported by growing consumer goods manufacturing in Brazil and Mexico. The Middle East & Africa region shows gradual growth driven by food import packaging, industrial diversification, and rising investments in local manufacturing.

Future Outlook

The future of the C wrap labelling machine market will be shaped by increasing automation, smart manufacturing, and sustainable packaging trends. Machine designs will continue to evolve toward higher speeds, greater accuracy, and reduced downtime through advanced sensors, artificial intelligence-assisted inspection, and digital control systems. Demand for flexible machines capable of handling multiple product sizes and label types will rise as manufacturers seek to respond quickly to changing consumer preferences. Energy-efficient motors and low-waste adhesive systems will gain importance as companies focus on reducing operational costs and environmental impact. Integration of labelling machines with enterprise resource planning, manufacturing execution systems, and track-and-trace platforms will become more common. As regulatory requirements for product identification and anti-counterfeiting intensify, demand for high-precision C wrap labelling solutions is expected to remain strong across regulated industries.

Conclusion

The C wrap labelling machine market plays a vital role in modern packaging operations by ensuring accurate, visually appealing, and regulation-compliant product labeling across diverse industries. Market growth is driven by the rapid expansion of packaged food, pharmaceuticals, and consumer goods manufacturing, along with rising demand for automation and operational efficiency. While challenges such as high capital costs, technical integration complexity, and maintenance requirements persist, continuous innovation in smart labelling technologies and growing demand from emerging economies are strengthening the long-term outlook. Asia-Pacific remains the primary growth engine, while Europe and North America contribute through advanced automation adoption and regulatory-driven demand. As manufacturers continue to prioritize productivity, brand presentation, and traceability, C wrap labelling machines will remain a critical element of modern packaging infrastructure.