Hoist Sling Chains Assemblie Segment Outlook: Targeting High-Growth Applications

The Hoist Sling Chains Assemblie Market is expanding as industries increasingly seek reliable, high-capacity lifting solutions. These assemblies are critical for material handling operations across construction, mining, logistics, automotive, oil & gas, and heavy engineering sectors. Their strength, flexibility, and durability make them ideal for lifting heavy and irregular loads, improving efficiency while ensuring worker safety.

The market is segmented based on chain type, material, leg configuration, and application. Single-leg, multi-leg, and custom chain assemblies cater to different load-handling requirements, while high-grade alloy steel chains provide superior strength and corrosion resistance. End-use applications such as construction, industrial manufacturing, and energy production are driving the demand for specialized solutions that meet precise lifting and load-bearing requirements.

Technological advancements are transforming market offerings. Manufacturers are integrating heat-treated alloy chains, corrosion-resistant coatings, and precise welding techniques to enhance durability and load capacity. Customization options allow users to select chain length, load capacity, and sling configurations, enabling safer and more efficient lifting operations. Automation and smart monitoring systems are also emerging trends, allowing real-time tracking of chain usage and predictive maintenance to prevent failures.

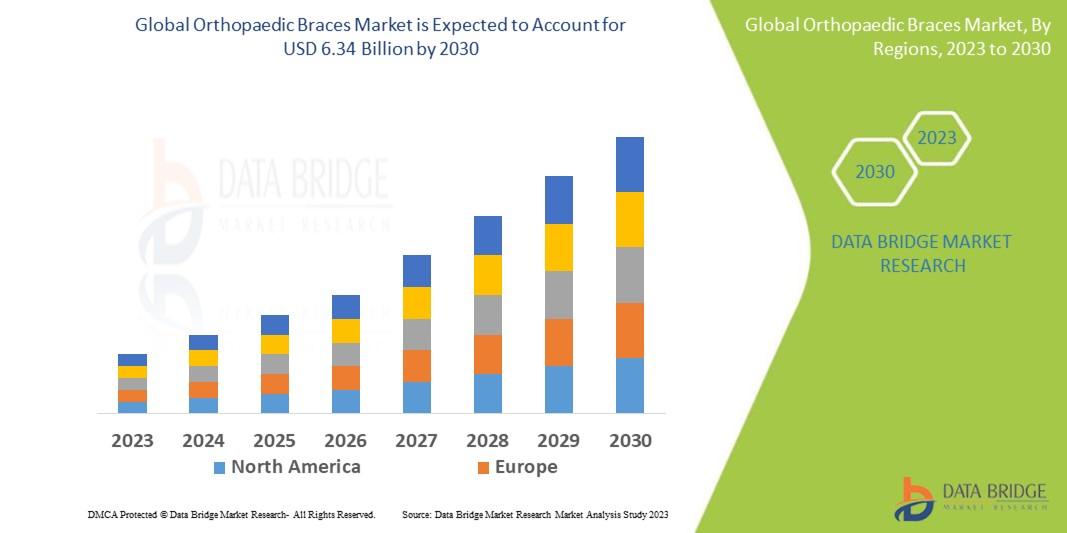

A comprehensive hoist sling chains assemblie segment outlook highlights strong growth potential in aerospace, automotive, and industrial applications due to high lifting demands and safety compliance requirements. North America and Europe dominate the market with established construction and industrial sectors, while Asia-Pacific is projected to experience the fastest growth, driven by large-scale infrastructure projects, industrialization, and expanding manufacturing capabilities. Latin America and the Middle East are emerging markets, with demand increasing in mining, oil & gas, and commercial sectors.

Manufacturers focusing on innovative, high-performance, and certified chain assemblies are poised to capture significant market share. Sustainability is becoming increasingly important, with eco-friendly production processes and recyclable materials gaining traction. Companies that prioritize safety, customization, and material quality are likely to secure a competitive advantage.

The Hoist Sling Chains Assemblie Market is expected to maintain steady growth in the coming years, driven by industrial expansion, rising safety standards, and technological innovations. Manufacturers who align product development with regional demands and emerging industry requirements will be well-positioned for long-term success.

Browse More: