Impact of Healthcare Expansion on the Radiation Shielding Material Market

The global focus on radiation safety has expanded rapidly in recent years, largely driven by the increasing use of high-energy imaging and industrial equipment. Healthcare providers, research facilities, nuclear plants, and advanced manufacturing sites all rely on radiation-emitting systems for critical operations. As these sectors grow, so does the need for robust shielding solutions capable of protecting workers, patients, and sensitive instruments. Rising government regulations and stricter safety protocols are also motivating organizations to adopt high-performance shielding materials that align with international standards. This shift is not only improving safety but also transforming how industries choose and implement protective technologies.

With regulatory bodies enforcing more stringent safety guidelines, interest in the Radiation Shielding Material Market has gained significant momentum. Organizations are now prioritizing materials that offer durability, cost-efficiency, and strong attenuation capabilities without compromising workflow or flexibility. This shift is particularly evident in sectors undergoing rapid digital transformation.

A complementary dimension to this expansion comes from in-depth studies such as Radiation Shielding Material Market Outlook, which help businesses understand future opportunities and challenges. These outlook analyses evaluate crucial indicators including capacity expansion, technology integration, end-user adoption patterns, and investment momentum across multiple regions. As competition intensifies, market outlook assessments are becoming central to long-term planning and strategic execution.

Material innovation remains at the heart of industry transformation. Lead, once considered the gold standard for radiation protection, is increasingly supplemented—or replaced—by advanced alternatives that address environmental and performance concerns. Non-lead composites, tungsten-reinforced polymers, and engineered thermoplastics offer improved sustainability, reduced weight, and easier installation. These materials enable manufacturers to create more ergonomic protective gear, modular shielding systems, and mobile barriers that support modern operational workflows. Technological advancements are also leading to the development of laminated shielding structures, multi-layered panels, and transparent radiation-resistant materials.

The medical imaging sector continues to drive the highest adoption, fueled by the expansion of diagnostic centers, mobile imaging units, and oncology departments worldwide. Radiation shielding is essential in controlling exposure from X-ray suites, fluoroscopy rooms, CT scans, and radiation therapy machines. The nuclear segment is seeing renewed investment as more countries adopt nuclear power to meet carbon neutrality goals. Industrial sectors are also increasingly reliant on shielding solutions to support radiography testing, sterilization processes, and material analysis operations.

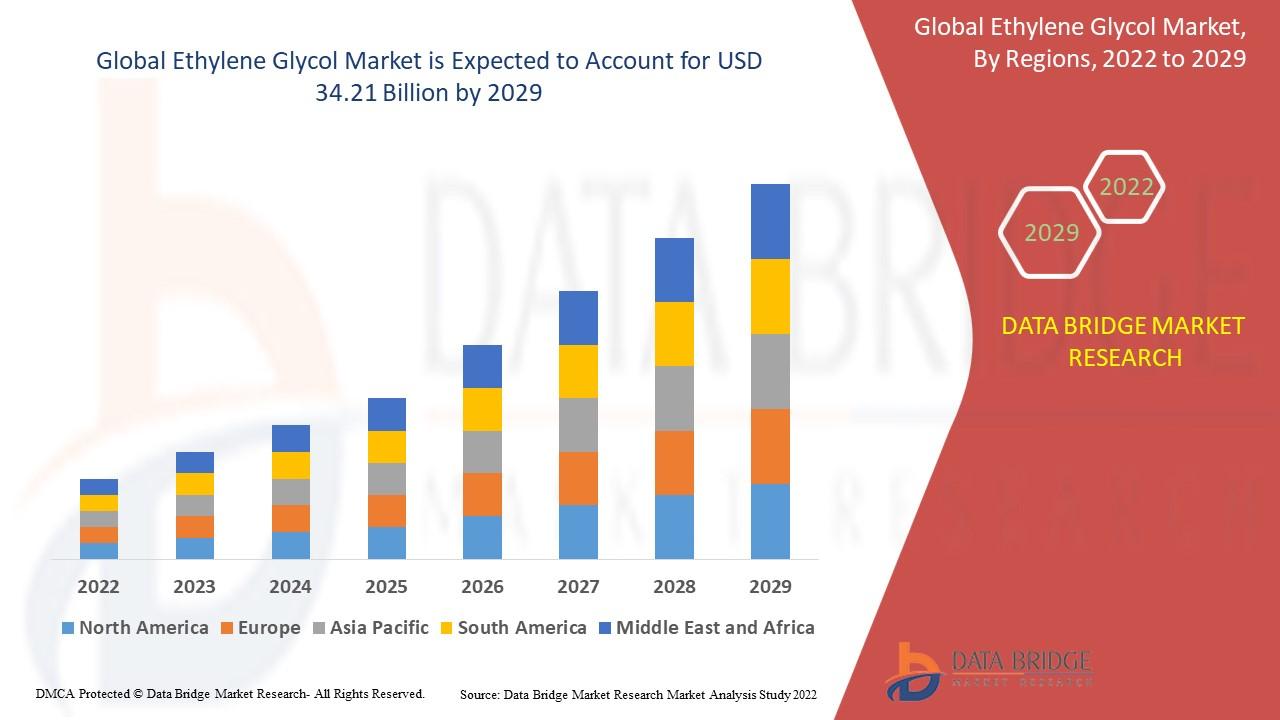

Regional trends highlight distinct growth pathways. While North America dominates in terms of technological sophistication and regulatory rigor, Asia-Pacific is expanding the fastest due to its growing healthcare infrastructure and nuclear development initiatives. Europe continues to lead in sustainability-focused material innovation, while the Middle East shows rising potential with investments in research and energy diversification.

Future prospects for this market remain exceptionally strong. Advancements in material science, automation, and digital monitoring systems are expected to accelerate innovation. Companies prioritizing environmentally responsible materials, lifecycle efficiency, and precision-engineered shielding solutions will be positioned to thrive in the evolving global landscape.

Related Report