How Can Fracturing Fluid Chemical Improve Hydraulic Efficiency Today?

In modern energy extraction, the role of Fracturing Fluid Chemical cannot be understated. Its precise composition ensures hydraulic operations achieve optimal flow and efficiency while maintaining environmental responsibility. Hengfeng has invested in advanced research to refine these formulations, balancing performance with sustainability. For engineers and operators, this chemical is more than a mixture; it is a tool to maximize productivity while minimizing operational risks.

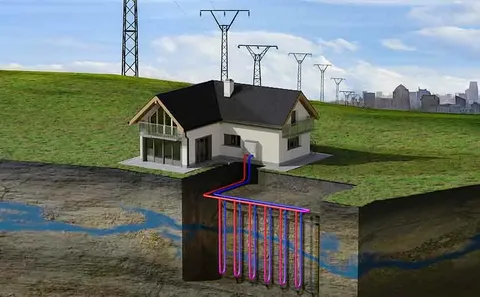

Hydraulic fracturing relies on well-prepared fluids to transport proppants into underground formations. A fluid that flows smoothly, resists degradation, and maintains viscosity under extreme conditions ensures operational continuity. Selecting a high-quality formulation means less downtime, consistent production, and lower maintenance requirements. It also helps companies adhere to environmental regulations by reducing contamination risk and improving fluid recovery.

Designing a superior product requires careful attention to polymer type, concentration, and additive synergy. When blended correctly, these elements improve friction reduction, increase pumping efficiency, and provide reliable performance under varying temperatures and pressures. These considerations make it a critical component in every project, from small-scale wells to large industrial operations.

Beyond performance, safety and ecological impact play a central role. Modern industries are increasingly accountable for the fluids they use and discharge. Optimized formulations reduce the need for excessive chemical volumes while achieving equivalent or better results, which translates into less environmental strain. Hengfeng's solutions embody this principle, combining innovation, efficiency, and responsibility in a single product line.

For industrial managers, understanding the science behind these compounds is essential. Proper training, monitoring, and fluid testing ensure maximum utility and compliance. When applied correctly, these fluids enhance operational control, prevent unexpected failures, and promote smoother project execution. Integration into a comprehensive fracturing strategy allows operators to maintain productivity without compromising environmental standards.

Collaboration between field engineers, chemists, and safety teams ensures that each application meets its technical and regulatory objectives. From selecting the right polymer type to monitoring viscosity and filtration properties, each step reinforces operational reliability. The cumulative effect of these considerations is a more predictable, efficient, and responsible hydraulic fracturing process.

In the rapidly evolving energy sector, staying ahead of chemical performance trends can distinguish industry leaders from the rest. Companies that invest in premium solutions gain operational advantages and build trust with stakeholders, regulators, and the wider community.

To explore high-performance solutions designed for efficiency and sustainability, visit https://www.polyacrylamidefactory.com/news/industry-news/understanding-fracturing-fluid-chemical-composition-function-and-applications.html , where innovation meets responsible industrial practice.